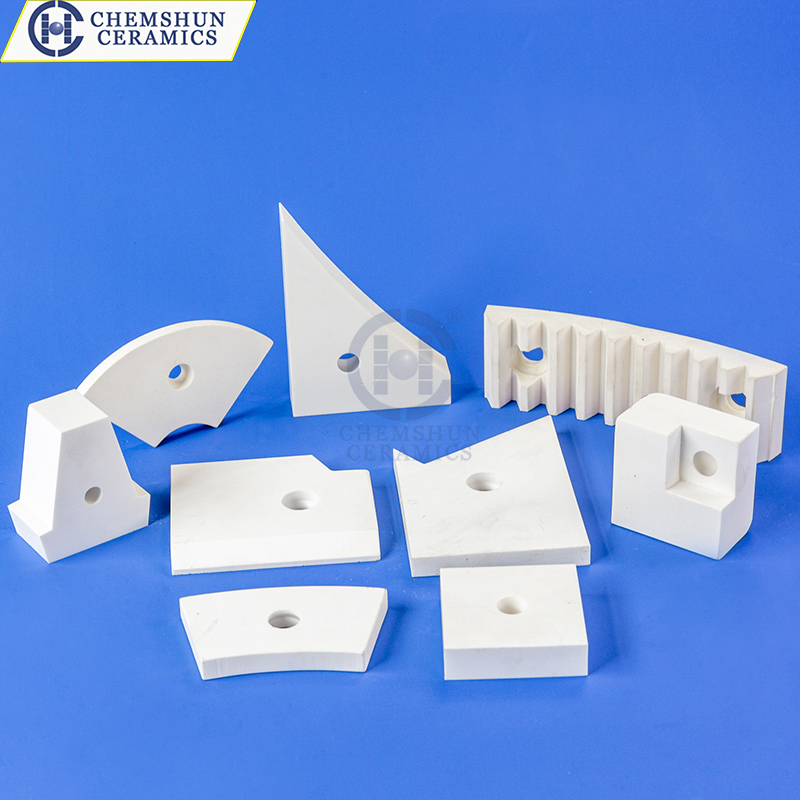

Alumina Ceramic Wear Plate yeIndasitiri Maintance

Feature

· Yakanakisa corrosion resistance property

· Kubatwa nyore kukura uye uremu

· Yakanakisa kupisa kupisa pfuma

· Yakanakisa kukanganisa kupikisa pfuma

· Kuiswa nekukurumidza uye kwakachengeteka

· Mutengo wekugadzira nekugadzirisa wakaderera

Chemshun Ceramic Advantages

· Professional tekinoroji timu kuti iwane CAD magadzirirwo

· Nyanzvi yekuisa timu kuti ikwanise kuisa sevhisi

· Yakanyatso kusimbiswa maitiro sekuenderana nepasirese zviyero

· Gamuchira akajairwa uye akafanogadzirwa mataira

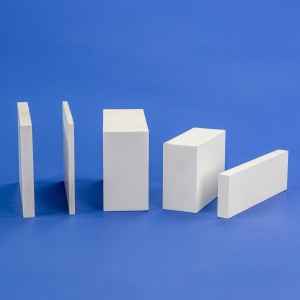

Dimensions

| CHINHU NO. | PRODUCT | KURERA x UPANZI | KUKORA | Q'TY PER BOX |

| mm | mm | pcs | ||

| 1 | PLAIN TILE | 100 x 100 | 6 | 50 |

| 2 | PLAIN TILE | 100 x 100 | 12 | 20 |

| 3 | PLAIN TILE | 100 x 100 | 15 | 15 |

| 4 | PLAIN TILE | 100 x 100 | 25 | 10 |

| 5 | PLAIN TILE | 100 x 100 | 50 | 5 |

| 6 | PLAIN TILE | 100 x 25 | 6 | 135 |

| 7 | PLAIN TILE | 150 x 100 | 6 | 50 |

| 8 | PLAIN TILE | 150 x 100 | 12 | 20 |

| 9 | PLAIN TILE-GAKANYANYA | 150 x 100 | 12 | 20 |

| 10 | PLAIN TILE | 150 x 100 | 15 | 15 |

| 11 | PLAIN TILE | 150 x 100 | 25 | 10 |

| 12 | PLAIN TILE-GAKANYANYA | 150 x 100 | 25 | 10 |

| 13 | PLAIN TILE | 150 x 100 | 50 | 5 |

| 14 | PLAIN TILE | 150 x 50 | 12 | 40 |

| 15 | PLAIN TILE | 150 x 50 | 25 | 20 |

| 16 | PLAIN TILE | 150 x 25 | 6 | 135 |

| 17 | PIPE TILE | 150 x 31/35 | 12 | 57 |

| 18 | PIPE TILE | 150 x 39/42 | 12 | 40 |

| 19 | PIPE TILE | 150 x 50/53 | 12 | 40 |

| 20 | PIPE TILE | 150 x 45/47 | 12 | 40 |

| 21 | PIPE TILE | 150 x 27/35 | 25 | 20 |

| 22 | PIPE TILE | 150 x 35/42 | 25 | 20 |

| 23 | PIPE TILE | 150 x 47/53 | 25 | 20 |

| 24 | PIPE TILE | 150 x 43/47 | 25 | 20 |

| 25 | PIPE TILE | 150 x 43/47 | 50 | 10 |

| 26 | WELDABLE TILE | 100 x 100 | 12 | 20 |

| 27 | WELDABLE TILE | 100 x 100 | 15 | 16 |

| 28 | WELDABLE TILE | 100 x 100 | 25 | 10 |

| 29 | WELDABLE TILE | 100 x 100 | 50 | 5 |

| 30 | WELDABLE TILE | 150 x 100 | 12 | 20 |

| 31 | WELDABLE TILE | 150 x 100 | 15 | 16 |

| 32 | WELDABLE TILE | 150 x 100 | 25 | 10 |

| 33 | WELDABLE TILE | 150 x 100 | 50 | 5 |

Application muIndustries

| Indasitiri | Equipment system | Equipment zvikamu |

| Simende | Pre-kusanganisa system yekurovera limestone uye crude fuel | Chute, bunker, pulley lagging, discharge cone |

| Raw mill system | Dyisa chute, ring yekuchengeta, scraper plate, seal ring, pipeline, bucket guard, cyclone, poda concentrator body, bunker | |

| Simende chigayo system | Chute, bunker, fan vane vhiri, fan casing, cyclone, denderedzwa duct, conveyer | |

| Ball mill system | Pulverizer exhauster muviri uye vane vhiri, muviri wepoda concentrator, pombi yemarasha yakapwanyika, hot air duct | |

| Sintering system | Inlet/outlet bend, wind value plate, chamupupuri, chute, pombi yekuunganidza huruva | |

| Afterheat system | Separator's pipeline nemadziro | |

| Simbi | Raw material feeding system | Hopper, silo |

| Batching system | Kusanganisa bunker, kusanganisa mbiya, kusanganisa dhisiki, disk pelletizer | |

| Sintered material transport system | Hopper, silo | |

| Dedusting uye Ash discharge system | Kubvisa pombi, bend, y-chidimbu | |

| Coking system | Coke hopper | |

| Chigayo chepakati-kumhanya | Koni, mabhururu ekuparadzanisa, pombi yekubuda nayo, pombi yemarasha yakapwanyika, moto wemoto | |

| Chigayo chebhora | Classifier, cyclone separator, bend, poda concentrator yemukati goko | |

| Kupisa simba | Coal handling system | Bucket vhiri muchina, marasha hopper, marasha feeder, orifice |

| Ball mill system | Separator pombi, gokora nekoni, gokora rechigayo uye chubhu yakatwasuka. | |

| Chigayo chepakati-kumhanya | mazimbe chigayo muviri, kupatsanurwa buffles, koni, pombi, gokora | |

| Chigayo | Pombi yemarasha yakaputswa nemagokora | |

| Dedusting system | Dedusting's pipeline uye gokora | |

| Ash discharge system | Fan duster's shell, pipeline | |

| Port | Kutakura zvinhu system | Bucket vhiri muchina dhisiki uye hopper, yekutamisa poindi hopper, unloader's hopper, |

| Kunyunguduka | Kutakura zvinhu system | Yekuyeresa hopper, coke hopper, chute yescreen inodedera, vharafu yemusoro, bhini repakati, bhini remuswe |

| Batching system | batch hopper, muchina wekusanganisa | |

| Burning system | Ash bhakiti, pombi calcine chubhu, hopper | |

| Dedusting system | Dedusting's pipeline uye gokora | |

| Chemical | Kutakura zvinhu system | Hopper, silo |

| Dedusting system | Dedusting's pipeline uye gokora | |

| Processing midziyo | Vibromill liner | |

| Marasha | Coal handling system | Bucket vhiri muchina, marasha hopper, marasha feeder |

| Marasha washing system | Hydrocyclone | |

| Mining | Kutakura zvinhu system | Hopper, silo |

Technical Data Sheet

| S.No. | Attributes | Unit | CHEMSHUN 92 I | CHEMSHUN92 II | CHEMSHUN 95 | CHEMSHUN ZTA |

| 1 | Alumina Content | % | 92 | 92 | 95 | 70-75 |

| ZrO2 | % | 25-30 | ||||

| 2 | Density | g/cc | ≥3.60 | ≥3.60 | >3.65 | ≥4.2 |

| 3 | Color | - | Chena | Chena | Chena | Chena |

| 4 | Kutora Mvura | % | <0.01 | <0.01 | 0 | 0 |

| 5 | Flexural Strength | Mpa | 270 | 300 | 320 | 680 |

| 6 | Moh's Density | Giredhi | 9 | 9 | 9 | 9 |

| 7 | Rock Zvakanaka Kuoma | HRA | 80 | 85 | 87 | 90 |

| 8 | Vickers Hardness(HV5) | Kg/mm2 | 1000 | 1150 | 1200 | 1300 |

| 9 | Kuputsika Kusimba (Mini) | MPa.m1/2 | 1000 | 3-4 | 3-4 | 4-5 |

| 10 | Kudzvinyirira simba | Mpa | 850 | 850 | 870 | 1500 |

| 11 | Thermal Kuwedzera Coefficient (25-1000ºC) | 1×10-6/ºC | 8 | 7.6 | 8.1 | 8.3 |

| 12 | Maximum oparesheni tembiricha | ºC | 1450 | 1450 | 1500 | 1500 |

Product Tags

Nyora meseji yako pano uye titumire kwatiri