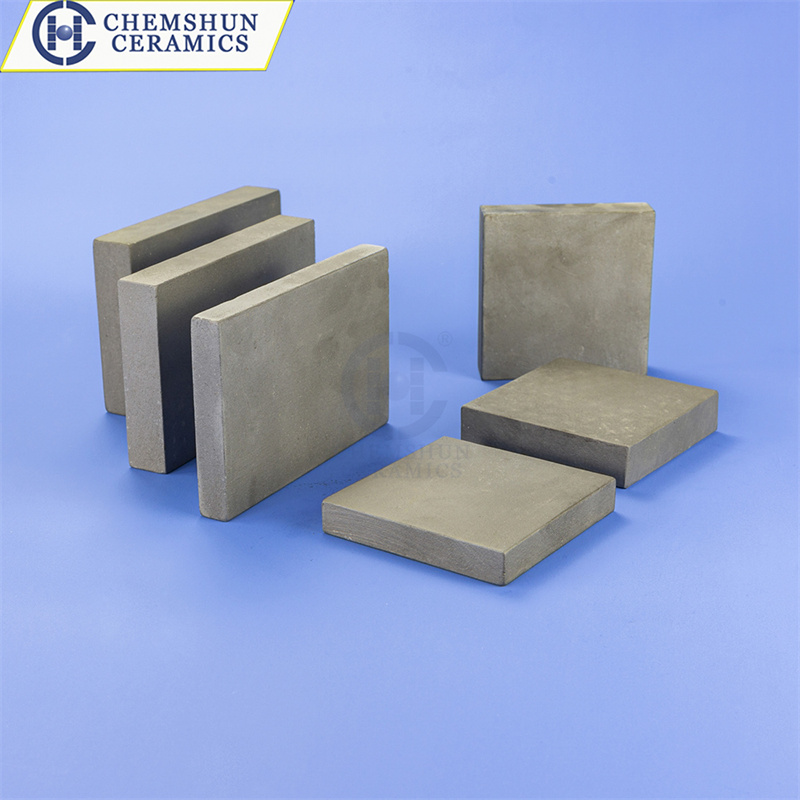

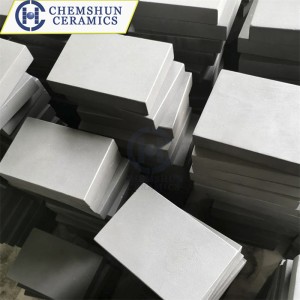

Reaction Bonded Silicon Carbide Tile

Zvakanakira Reaction Bonded Silicon Carbide

1) Low density.

2) Corrosion resistance.

3) Pfeka kuramba.

4) Oxidation kuramba.

5) Abrasion kuramba.

6) Yakanaka kupisa kutyisa kupikisa (nekuda kwekuderera kwekuwedzera kwemafuta ekuwedzera uye yakakwirira yekupisa conductivity).

7) Yakanakisa Simba pakupisa kwakanyanya.

8) Yakanaka dimensional kudzora kwezvimiro zvakaoma.

Pfeka Zvigadzirwa Zvinodzivirira: Silicon carbide ndiro, Silicon carbide zvidhinha, Pipe lining, Pipe Cone, dutu, nezvimwewo.

Kiln fenicha: Plate, Beam, Roller, Burner Nozzle, Round danda, square danda, gomba danda.Crucible, Sagger, nezvimwewo.

Zvimwe: Desulfurization nozzles

Kushandiswa kweReaction Bonded Silicon Carbide:

Reaction bonded silicon carbide yakaratidza kuve yakanakisa sarudzo yekupfeka senge pombi liner, Nozzles, kuyerera kwekudzora kuvhuvhuta uye makuru mapfekero ekupfeka mumigodhi pamwe nemamwe maindasitiri.

Main Parameter

| Properties | Units | SiSiC/RBSIC |

| Kuwanda kwehuwandu (SiC) | V01% | ≥85 |

| Bulk density | g/cm3 | 3.01 |

| Inooneka porosity | % | <0.1 |

| Modulus yekuputika pa20 ℃ | Mpa | 250 |

| Modulus yekuputika pa1200 ℃ | Mpa | 280 |

| Modulus ye elasticity pa20 ℃ | Gpa | 330 |

| Kutsemuka kuomarara | Mpa*m1/2 | 3.3 |

| Thermal Conductivity pa1200 ℃ | wm-1.k-1 | 45 |

| Thermal kuwedzera pa1200 ℃ | a×10-6/℃ | 4.5 |

| Thermal shock resistance pa1200 ℃ | Kugona chose | |

| Coefficient of heat radiation | <0.9 | |

| Max.kushanda tembiricha | ℃ | 1350 |

Size

inogona kugadzirwa maererano nezvinodiwa nevatengi.

Service

Tinobvuma mirairo yetsika.

Kana iwe uchida kuziva rumwe ruzivo rwechigadzirwa, gamuchirwa kuti ubate nesu uye isu tichakupa iwe chakanyanya kukodzera chigadzirwa uye yakanakisa sevhisi!